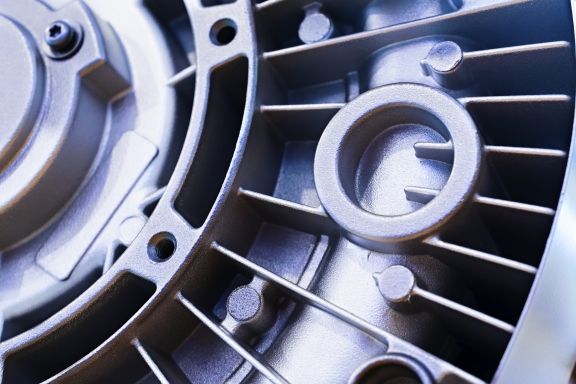

a manufacturing process in which molten low melting point metal, such as aluminum, zinc and magnesium, is forced rapidly under high pressure into steel molds made of heat resistant steel, and immediately cooled and shaped by the steel molds. The characteristics of die casting encompassing high productivity, high precision in size, less post processing, smooth and glossy product surface finish, high mechanical strength and capability of manufacturing thin-wall products, allow the applications in products with complex structure, such as automotive parts, 3C and electrical products.